Process Analysis

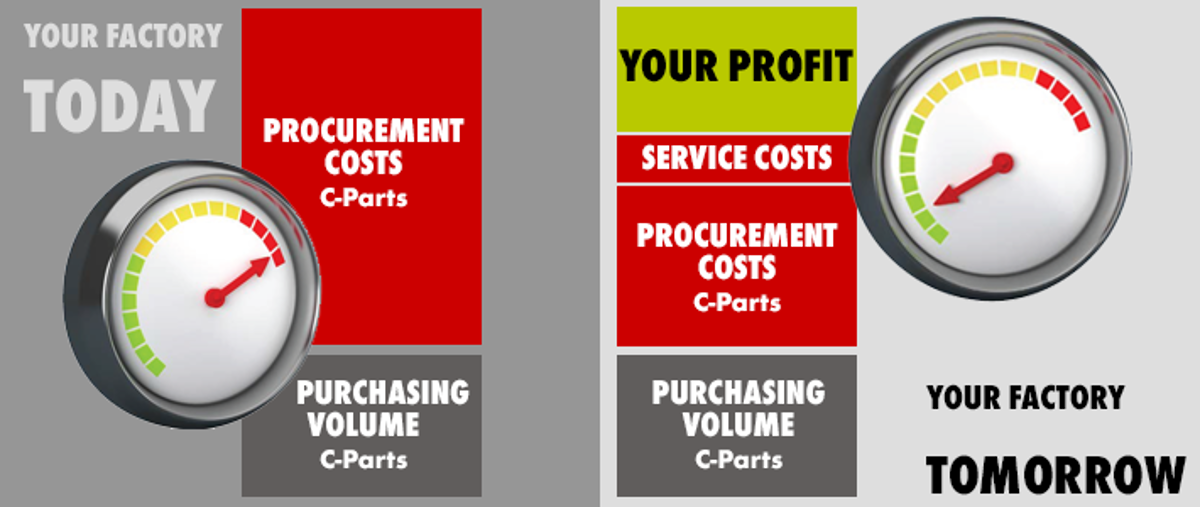

C-Parts – without doubt not the most important components of a plant or machine. These parts only account for 5% of the entire purchasing volume in production. Yet they constitute 75% of the procurement costs.

Do you recognize yourself here?

Manual ordering procedures, coordination of a large number of suppliers, countless goods deliveries as well as goods receipt postings, incalculable financial audits and the nearly impossible challenge of responding to demand peaks are still on the agenda of many industrial companies.

Is that really still relevant? Let us tell you: Certainly not!

Your internal process analysis for C-Parts today and tomorrow:

We will whip your productivity and cost efficiency into shape!

C-Parts management is only successful once your procurement processes and intra-logistics have been optimised. This is done by reducing procurement costs, item diversity and the number of suppliers, which will then free capacities for your core activities and reduce process costs.

With an integrated concept for your production and operational equipment tailored to your needs, your industry and quantity requirements, we can sustainably reduce your procurements costs. Our solutions are based directly on the demand location and point of use in your purchasing, procurement, maintenance, material management, warehousing and production departments.