Through long-term cooperation with many leading suppliers in the wind industry, Würth Industry China has designed comprehensive solutions for all aspects of the wind industry to solve the problems in the working.

Through long-term cooperation with many leading suppliers in the wind industry, Würth Industry China has designed comprehensive solutions for all aspects of the wind industry to solve the problems in the working.

Through long-term cooperation with many leading suppliers in the wind industry, Würth Industry China has designed a perfect solution by combining our own products, supply chain, services and other advantages to meet the actual needs of the wind energy industry. We contribute to China's goal of carbon neutralization in this way.

Personal Protective Equipment

Würth can provide you with more than 25000 types of PPE, including eyes, hearing, hands, respiratory system, skin protective equipment and protective clothing, safety shoes, fall protective equipment, first aid equipment, etc.

For high-altitude operations such as the installation, operation and maintenance of wind turbines, the safety of fall protection products is the top priority. Würth fall protection products meet EN 361, EN358 and EN 353-1 standards, and provide workers with a comfortable wearing experience while ensuring safety and effectiveness. Your aerial work can also enjoy a sense of security like walking on the ground.

Fasteners

As an industry leader in the field of connection technology, Würth provides all kinds of fasteners for various industries. Wind power equipment is faced with adverse operating conditions such as high-altitude applications, heavy weight, complex wind load, large temperature difference and so on. The reliability of fasteners is directly related to the safety of wind turbine operation.

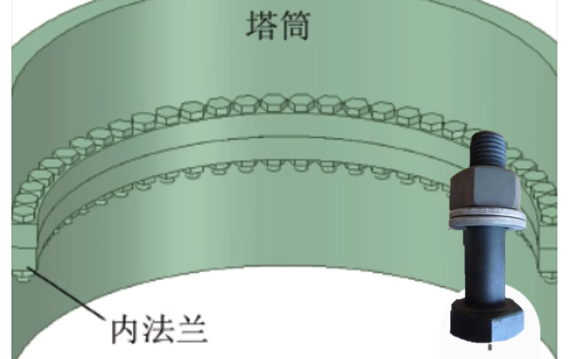

Take the connection of the tower tube as an example. The tower tube is the main bearing component of the wind turbine, which mainly plays a supporting role in the wind turbine. At the same time, it absorbs the vibration of the wind turbine and is used for the connection of the tower tube. It can never be separated from a kind of fastener, the steel structure connection kit, also known as the steel structure connection pair. Würth EN14399 steel structure connection kit is an upgraded product on the basis of the original DIN6914, 6915, 6916. Apart from the fact that the size of this series of products is larger than that of traditional hexagonal products and the length of the bolt rod is larger, it focuses on the detailed classification of the torque coefficient of the components. The higher the accuracy of the torque coefficient, the simpler the corresponding installation mode. On the contrary, the lower the precision of the torque coefficient is, the higher the installation mode is. This subdivision can effectively help the steel structure designer to make the best choice between cost and installation efficiency.

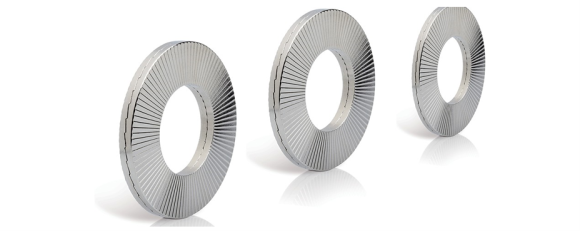

For the fixing of tower tube after crimping, we recommend the fastening connection of Monotail short tail rivets for flat plate parts. The installation method of this kind of products is to directly act the tension on the nail core bolt and squeeze the riveted pipe to retain the tension relatively intact on the nail core bolt to realize the installation of fixed axis force. This kind of products can effectively avoid the dispersion of pre-tightening force caused by the discretization of friction coefficient of traditional threaded fasteners. The single slot design has stronger adaptability to the environment.

At present, there are 60, 000 products in Würth Haiyan CDC, including all kinds of standard fasteners, such as DIN/ISO/ANSI/GB standard parts. In addition to standard parts, we have a team of engineers to define fasteners that are designed for different scenarios. In addition, we also provide customers with customized parts and drawings that meet various needs. At the same time, our quality laboratory can cover all the major testing categories involved in the fastener industry standards at home and abroad to meet your one-stop demand for fastener procurement.

Services Never End

Once the wind turbine has problems, the on-site staff need to carry out maintenance at high altitude with testing tools, which is not only costly, but also puts forward extremely high requirements for the professional ability of the maintenance personnel. When the wind factory finds that the fan has a fault that they cannot solve immediately, and the experts are unable to come to the site immediately, it is bound to cause the loss of power generation. Würth and Microsoft jointly developed the HoloMaintenance mixed reality remote maintenance platform with Hololens to solve this kind of problems.

The staff of can put on the mixed reality glasses, log on to HoloMaintenance and remotely connect with the experts. Through the video stream in the program, experts can remotely see the same scenes and objects as the staff. They can insert images, charts and useful marks into the field of vision of the staff's glasses, assist and guide the on-site operators to carry out equipment maintenance, so that the operators can free their hands and make the operation and maintenance easier.

Wind Turbines are usually located in remote areas with inconvenient procurement and transportation difficulties. Würth can tailor container solutions for material supply, installation, operation and maintenance related to the project. We can provide a full range of services such as container design, material recommendation and supply, transportation and assembly. We can also provide timely supply and local delivery to the project site with limited logistics resources. For customers carrying out large-scale hydropower, wind power, oil and other projects, our services can greatly improve the level and efficiency of installation, operation and maintenance material management.